Dyehouse Machines

Mathis brand Laboratory Tube Dyeing Machine

Number: 1

Model: —

Kodu: Mr-03367

Mathis Beaker Dyeing Machine, type P, 24 tubes, Eliar TBB 100 controller, Switzerland made, Schneider invertor, installed and running situation, Textile, yarns in hank form and knitted goods are treated in this machine.

Mathis brand Laboratory Tube Dyeing Machine

Number: 1

Model: —

Kodu: Mr-03368

Mathis Beaker Dyeing Machine, type P, 24 tubes, controller is available, Switzerland made, invertor, at warehouse (Textile, yarns in hank form and knitted goods are treated in this machine).

Laboratory Tube Dyeing Machine

Number: 1

Model: —

Kodu: Mr-03370

Europen made Beaker (Tube) Dyeing Machine, 24 tubes, at warehouse.

Kaymak Makina Sample Jet Machine

Number: 1

Model: 2005

Kodu: Mr-03516

Kaymak Brand Sample Jet Machine, 15 kg, 2005 model, with Setex programmer, running situation.

Rapid Laboratory Scuba Paint

Number: 1

Model: 2016

Kodu: Mr-03653

Rapid Brand Beaker (Tube) Dyeing Machine, 2016 model, 4 tubes, running situation.

Logic Art- Data Color Autolab TF-120 Pipetting Machine

Number: 1

Model: 2005

Kodu: Mr-03683

Logic Art- Data Color Autolab TF-120 Laboratory Dispenser Machine, (Taiwan made), 120 tube capacity, 2005 model, together with scaling and mixer unit, installed and running situation.

Mcs Sample Fabric Dyeing Machine

Number: 1

Model: 2004

Kodu: Mr-03725

MCS Brand Sample Fabric Dyeing Machine, 2004 model, 5 kg capacity, installed and running condition.

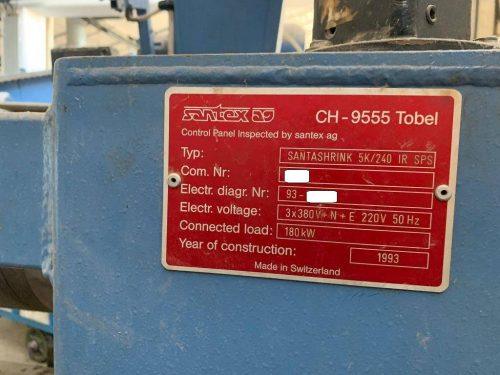

Santex Dryer

Number: 1

Model: 1993

Kodu: Mr-03758

Santex Drying Machine, 2.40 mt working width, 5 chamber, 1993 model, single padder, chain, double pass, net, Siemens PLC, brand new burners are fixed in 2008, gas heated, installed and running situation.

Lafer brand Shaving Machine

Number: 1

Model: 1998

Kodu: Mr-03241

Lafer Brand Shearing Machine, 2mt working width, 1998 model, underutilised, installed and running situation.

Lafer Turk Brand Shearing Machine

Number: 1

Model: 2012

Kodu: Mr-03722

Lafer Turk Brand Shearing Machine, 2.20 mt roll width, 2012 model, full digital control, Schneider touch screen, Schneider inverter, together with dust sucking unit, installed and running condition.

Lafer (Italian) Brand Shearing Machine

Number: 1

Model: 1997

Kodu: Mr-03723

Lafer (Italian) Brand Shearing Machine, 2.20 mt roll width, 1997 model, electronically reconditioned in July 2021, full digital control, installed and running situation.

Mario Crosta Shearing Machine

Number: 1

Model: 2004

Kodu: Mr-03829

Mario Crosta Shearing Machine, 3.40 mt working width, 3.60 mt roller width, 2004 model, with 1 pcs spare blade, installed and running condition.

Boyahane Makinaları (529)

Boyahane Makinaları (529) İplik Makinaları (218)

İplik Makinaları (218) Örme Makinaları (53)

Örme Makinaları (53) Dokuma Makinaları (137)

Dokuma Makinaları (137)